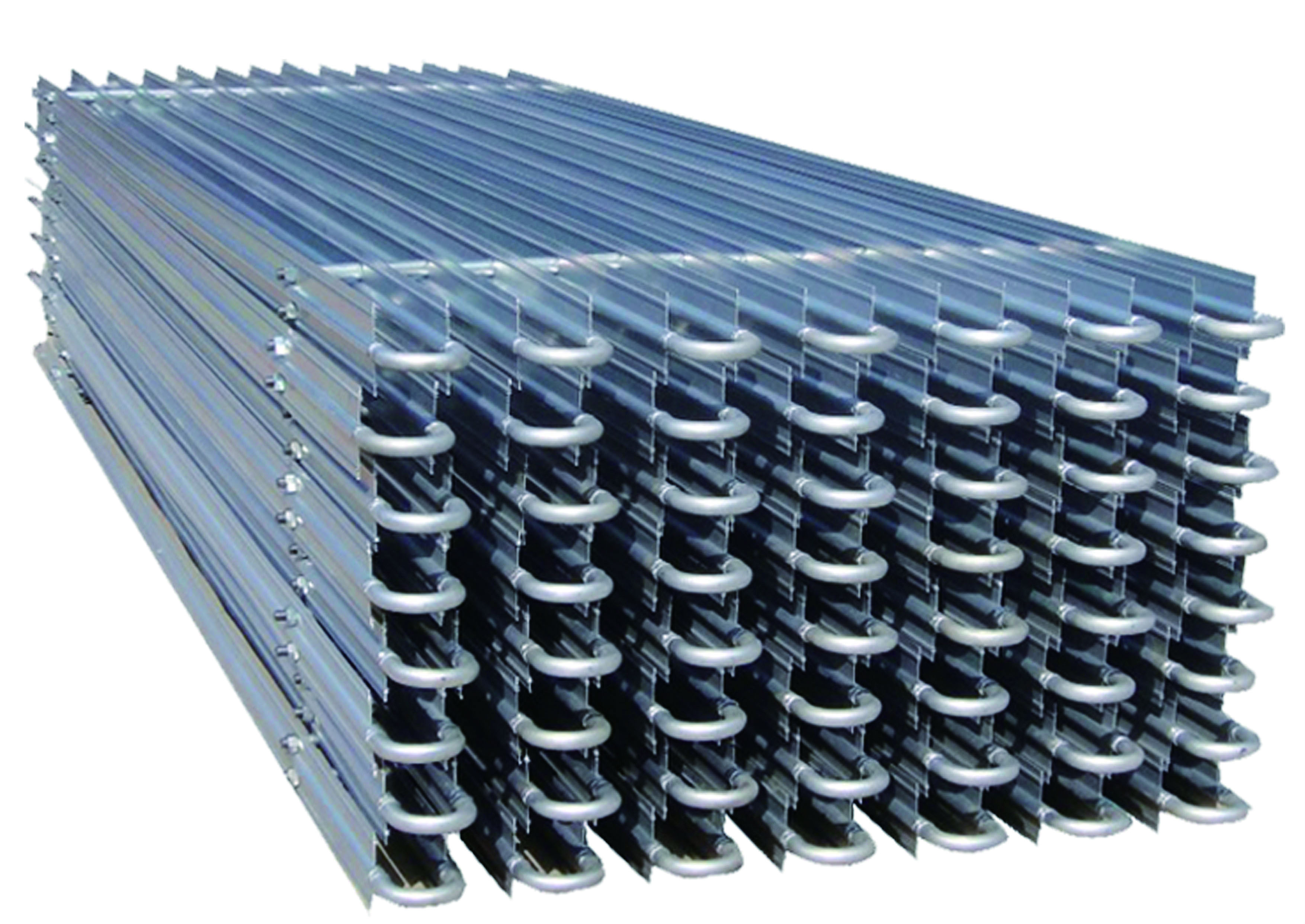

Energy-saving LvPai (aluminum alloy wing tube evaporator) as the fins and tube one die casting molding structure, mainly used in low temperature cold storage refrigeration system, is the ideal of all kinds of food freezing and cold storage of the evaporator.

Aluminum alloy quick-frozen is put aside frame exhaust pipe is used to replace seamless steel tube is put aside frame exhaust pipe of a new generation of products, widely used in the segmentation of meat, aquatic products, poultry, pasta, prepared food and some of the rapid freezing of fruits and vegetables food.

Main features:

1, the heat conduction performance is good, compared with the traditional steel ZhiLengShi evaporator, aluminum alloy has good heat conduction ability, at the same temperature under the condition of the coefficient of thermal conductivity of the green of 210 w/(㎡ ℃), steel only 46 w/(㎡ ℃).

2, type: mainly divided into more than two fin and the fin type.

3, increase heat exchange area of unit length: LvPai projection area and the area ratio of politics and law can do one than three or four, LvPai all can be installed in the cold storage on the ceiling, the unit area of the heat transfer ability row is more efficient than using a wall more energy efficient.

4. Light weight, convenient installation: the weight of per meter LvPai is only about one 5 of the steel row, greatly reduce the library in the cold storage building top load and all kinds of lifting the auxiliary material, improve the installation efficiency, reduces the installation costs.

5, less dosage of refrigerant: LvPai using the outer wing structure, filled volume of the refrigerant will be reduced greatly, can save cost of refrigerants.

6, dry food consumption: less LvPai hoisting in library, forming ZhiLengShi natural convection, cause the cooling material consumption reduced to a minimum.

7, exhaust pipe high pressure: aluminum fins and tube a die-casting molding structure, wing increased and the strength of the aluminum tube, aluminum tube pressure also increase greatly.

8, pipe inner surface smooth, after oxidation treatment, clean system running smoothly.

9, frozen goods from contact with the circular tube into plane contact, increase the heat transfer area, at the same time reducing the pressure on contact with the aluminum tube and wear and tear, improve the shelf life and safety coefficient.

10, oxidation treatment was conducted on the aluminum alloy plate surface of refrigerator, bracket is made of stainless steel square tube or shaped integral hot-dip zinc, connected to the refrigerator plate is made of stainless steel fittings. In use process need for anti-corrosion treatment, health condition is good, does not pollute the frozen goods.